LED strips are conventionally divided into two types: flexible LED strips and LED rigid strips. But generally it also includes the old-fashioned LED light strips connected to the circuit board with wires. Such as flat three-wire 4.3W/meter, flat four-wire 6.48W/meter, flat five-wire 8.64W/meter, etc.

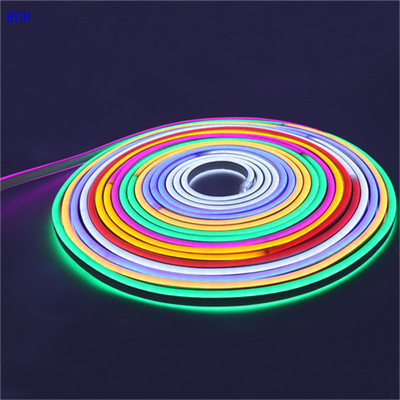

1. The flexible LED strip is assembled with FPC as circuit board and SMD LED. The thickness of the product is only 0.1CM, and it does not take up space. And it can be cut at will, and it can be extended at will without affecting the light emission. The FPC material is soft and can be bent, folded, and wound arbitrarily. It can be moved and stretched freely in three-dimensional space without breaking. It is suitable for use in irregular places and places with small spaces. It is also suitable for arbitrarily combining various patterns in advertising decoration.

2. The LED rigid light bar is assembled with PCB rigid board. LEDs can be assembled with SMD LEDs, and can also be assembled with direct-plug LEDs. Depending on the needs, different components are used. The advantage of the rigid light bar is that it is easier to fix, and it is more convenient to process and install. The disadvantage is that it cannot be bent at will and is not suitable for irregular places. There are 18 LEDs, 24 LEDs, 30 LEDs, 36 LEDs, 40 LEDs and many other specifications of SMD LEDs for rigid light bars. There are 18 LEDs, 24 LEDs, 36 LEDs, 48 LEDs and other different specifications. There are frontal and lateral ones, and the side-illuminated ones are also called Great Wall light bars.